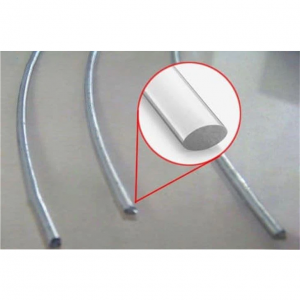

of elevator Steel Hlau hlua Class 8 × 19

Technical Data:

| Nominal txoj kab uas hla | Kwv yees li.hnyav | Yam tsawg kawg tawg load | |||

| 1370-1770N / hli2 | 1570N / hli 2 | 1770N / hli2 | 1960N / hli2 | ||

| mm | Kg / m | kN | |||

| 8 | 0.26 | 35.8 ib | 35.7 ib | 40.3 | 44.7 ib |

| 9 | 0.33 ib | 45.3 ib | 45.2 ib | 51 | 56.5 ib |

| 10 | 0.407 ib | 55.9 ua | 55.9 ua | 63 | 69.8 ua |

| 11 | 0.492 ib | 67.6 ib | 67.6 ib | 76.2 ib | 84.4 ib |

| 12 | 0.586 ib | 80.5 ua | 80.5 ua | 90.7 ua | 100 |

| 13 | 0.688 ib | 94.5 ua | 94 | 106 | 118 |

| 14 | 0.798 ib | 110 | 110 | 124 | 137 |

| 15 | 0.919 ib | 126 | 127 | 143 | 158 |

| 16 | 1.04 ib | 143 | 143 | 161 | 179 |

| 17 | 1.18 | 162 | 183 | 203 | |

| 18 | 1.32 ib | 181 | 204 | 226 | |

| 19 | 1.47 ib | 202 | 228 | 253 | |

| 20 | 1.63 ib | 224 | 252 | 279 | |

| 22 | 1.97 ib | 271 | 305 | 338 | |

| 24 | 2.34 ib | 322 | 363 | 402 | |

| 26 | 2.75 ib | ib 378 | 426 | 472 ib | |

| 27 | 2.97 ib | 408 | 460 | 509 ib | |

| 28 | 3.19 ib | 438 ib | 494 ib | 547 ib | |

| 29 | 3.43 ib | 472 ib | 532 ib | 589 ua | |

| 30 | 3.68 ib | 506 | 570 ib | 631 ib | |

| 32 | 4.17 ib | 572 ib | 645 ib | 715 ib | |

of the elevatorHlau Hlau RopeLuas 8 × 19

8 × 19 S + IWRC (1-9-9)

8x19W+IWRC (1-6-6+6)

8x25F+IWRC (1-6-6F+12)

8x26WS+IWRC (1-5-5+5-10)

Steel Chemistry:

Kev sib xyaw ntawm cov qib steel yog siv thiab cov txheej txheem kho cua sov los tsim cov qib mos, nruab nrab thiab tawv tensile.Cov lus hauv qab no tsuas yog qhia txog cov chemistry steel siv xwb.

| Qib Tensile | % Cov pa roj carbon | % Phosphorus | % Manganese | % Silicon | % Sulfur |

| Txuj | 0.45-0.50 Nws | 0.032 ib | 0.5 ~ 1.00 Nws | 0.10-0.34 Nws | 0.041 ib |

| Siab | 0.59-0.63 Nws | 0.035 ib | 0.5 ~ 1.10 | 0.10-0.35 Nws | 0.045 ib |

| Ntxiv-siab | 0.65-0.83 Nws | 0.035 ib | 0.5 ~ 1.10 | 0.10-0.35 Nws | 0.045 ib |

Lay direction: sab tes xis nteg

Ntawm kev thov kev xaiv: Galvanized / ungalvanized, sab laug tes, Dual tensile, greasing qib.

Steel Qib: High Carbon Steel Hlau Qws: 40 # 45 # 60 # 65 # 70 # 72A # 82B

Daim ntawv thov: of elevator

Lay: Sab tes xis tsis tu ncua (RRL);sab tes lang lay(RHLL);Sab laug tes tsis tu ncua (LHRL);Left hand lang lay (LHLL).

Cov khoom ntim: Ntoo reels, ntoo pallets, Kraft ntawv.

Kev lag luam Standard:

Ib qho: Ob chav steel qib ob lub zog, No. 45 steel, No. 65 steel, 1370N / mm2, 1770Mpa,

Ob: ib leeg steel tooj, ib lub zog, 65 steel, 1770N / mm2.Of elevator steel hlua cores yog sisal thiab PPC hluavtaws fibers raws li lub teb chaws tus qauv.Cov kev qhia tshwj xeeb thiab cov qauv ntawm kev ua haujlwm siab ceev hlau hlua yog 8 * 19S + 8 * 7 + pp, 8 * 19S + 8 * 7 + 1 * 19

Raws li ib txwm muaj, feem ntau ntawm cov hlua hlau tshiab tau lubricated thaum lub sij hawm tsim khoom, tab sis thaum siv, cov roj lubricating yuav raug txo.Raws li qhov tseeb tias lubrication tuaj yeem tsis tsuas yog tiv thaiv cov hlua hlau hlau los ntawm kev xeb thaum thauj thiab khaws cia, tab sis kuj txo qhov hnav ntawm cov xov hlau, nruab nrab ntawm cov hlua hlua thiab ntawm cov hlua hlau thiab cov hlua khi hlua khi thaum siv cov hlua khi. hlau hlua, thiab siv cov hlua txuas txuas ntxiv.Lub neej ntev kuj muaj txiaj ntsig zoo.Yog li ntawd, txhawm rau txo qhov kev puas tsuaj ntawm corrosion thiab hnav rau cov hlua hlau, nws yog ib qho tsim nyog yuav tsum tau ua cov tshuaj xyuas lubrication.Ua ntej ntawm tag nrho cov, nws yog ib qhov tsim nyog los xaiv qhov tsim nyog hlau hlua lubricating roj.Lub elevator hlau hlua lubricating roj yuav tsum yog ib qho kev sib txhuam tshwj xeeb roj nrog ib qho kev sib txhuam coefficient.Kev ua haujlwm siab hlau hlua lubricating roj yog qhov tseem ceeb lav rau kev tuav cov hlua hlau thiab ua kom lub neej ntev ntawm cov hlua hlau.Thaum cov hlau hlua hlau ua haujlwm, sab hauv nthuav tawm peb-dimensional fretting kev sib txhuam, uas yuav tsum tau cov hlau hlua roj yuav tsum muaj zog nkag mus rau hauv lub zog, uas yog, lubricating roj molecule los tiv thaiv hnav tus neeg saib xyuas nyob rau hauv lub lubricating roj tuaj yeem nkag mus rau hauv txhua lub hlau. hlau.Tsis tas li ntawd, cov hlau hlua roj yuav tsum muaj zog adhesion zog.los xyuas kom meej tias nws adheres tusyees rau txhua txoj hlua hlau.Feem ntau muaj ntau txoj hauv kev los lubricate thiab tswj cov hlua hlau.Ib qho yog disassemble cov hlua hlau thiab tsau rau hauv cov roj lubricating nrog qhov kub ntawm 80 txog 100 degrees rau li 2 mus rau 4 teev.Lwm qhov yog los txhuam cov roj nplaum ncaj qha rau ntawm txoj hlua hlau nrog txhuam.Tus yuam sij yog tus tswv txoj kev txhuam hniav thiab ncua sij hawm.Feem ntau hais lus, ib txoj hlua hlau uas muaj txoj kab uas hla ntawm 12 hli yog txhuam nrog txog 1 kg ntawm cov roj lubricating txhua 40 meters, thiab lub sijhawm txhuam hniav yog li ob lub lis piam;lwm qhov yog siv Cov khoom siv tshwj xeeb xaim hlua lubrication yog siv los lubricate cov hlua hlau.Txoj kev no yog qhov yooj yim tshaj plaws, tab sis tus nqi ntawm cov khoom siv yog siab.Cov txheej txheem lubricant thiab lubrication siv yuav tsum tau ua raws li qhov yuav tsum tau ua ntawm cov khoom siv hlau hlua.Tam sim no, tsis muaj ntau lub elevator tu tsev yeej tau them sai sai rau lub lubrication thiab tu cov hlua hlau.Ntau chav nyob tau raug siv los hloov cov hlua hlau tshiab yam tsis tau xyuam xim rau kev tswj xyuas lubrication.Qhov no tsuas yog ib qho ntawm qhov yuav tsum tau ua kom muaj kev nyab xeeb ntawm kev siv cov hlua hlau.Tsis tas li ntawd, nws tseem yuav tsum tau kuaj xyuas cov kab mob peripheral ntawm cov hlua hlau, xws li qhov chaw hnav ntawm lub traction sheave groove thiab geometry ntawm sheave zawj kom ntseeg tau tias cov hlua hlau ib txwm nyob hauv kev sib cuag zoo thaum lub sijhawm ua haujlwm kom tsis txhob muaj kev sib txhuam. .Xyuas kom muaj kev nyab xeeb ntawm lub elevator.

Peb: Kev txiav txim siab ntawm kev qaug zog lub neej ntawm steel hlau hlua rau elevator

Kev txiav txim siab ntawm lub neej qaug zog yuav tsum tau siv lub tshuab tshwj xeeb steel hlau hlua qaug zog kuaj tshuab, raws li lub teb chaws tus qauv GB / T12347-2008 steel hlau hlua dabtsi yog khoov qaug zog xeem txoj kev, los yog YB / T4288-2012 of elevator steel hlau hlua bending qaug zog xeem txoj kev .Qhov zoo ntawm elevator hlau ropes los ntawm cov tuam txhab sib txawv tuaj yeem sib piv, thiab kev ua haujlwm zoo ntawm elevator hlau ropes ntawm cov txheej txheem ntau lawm kuj tuaj yeem sib piv.

Cov manganese-based phosphating-coated of elevator hlau hlua thiab lub elevator xaim hlua hlua nrog tib txoj kab uas hla, cov qauv thiab kev ua tau zoo tau raug sim ua tiav ntawm lub tshuab kuaj qaug zog kom txog thaum thawj zaug tawg strand, lub neej qaug zog raug kaw, thiab cov ntaub ntawv xeem tau piv.Feem ntau, qhov ntev lub neej qaug zog, lub neej ua haujlwm ntev, thiab lawv yog proportional.Qhov ntev ntawm lub neej qaug zog, qhov siab dua qhov zoo ntawm lub elevator hlau hlua.